PVC Extrusion Compounds

At Dugdale, we have cultivated a reputation for excellence in the manufacturing of both standard and customised PVC extrusion compounds, which find widespread applications in PVC profile extrusion, PVC co-extrusion, and post co-extrusion processes.

The PVC extrusion process lies at the core of producing fixed cross-sectional PVC profile items, such as precision window frames amongst a whole host of other applications. This intricate process involves the feeding of PVC extrusion compound into an extruder via a hopper. The compound is melted and subsequently forced through a die to achieve the desired cross-sectional shape and dimensions.

The versatility of extruding is extremely beneficial, as it is capable of forming complex cross-sections even with inherently brittle materials. The PVC extrusion process places fewer stresses on the materials compared to alternative manufacturing methods, resulting in parts that boast an exceptional surface finish.

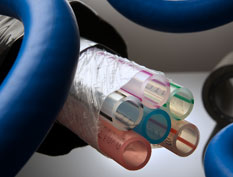

Our extensive experience spans several decades, during which Dugdale has been a trusted manufacturer of PVC extrusion compounds across a wide spectrum of industries and applications. This expertise extends beyond standard profile extrusion, but also encompasses post co-extrusion and co-extrusion processes. In these advanced techniques, compatible PVC extrusion compounds are strategically bonded together to create products that are not only stronger but also multifunctional.

Whether your specific needs involve PVC extrusion compounds for PVC profile extrusion, co-extrusion, or post co-extrusion applications, our highly knowledgeable Dugdale team is prepared to provide expert guidance. We offer a range of standard grades designed to meet the demands of most plastic extrusion applications. Additionally, we possess the technical prowess to engineer customised extrusion compounds tailored precisely to your unique specifications and requirements, ensuring optimal performance and quality in your projects.